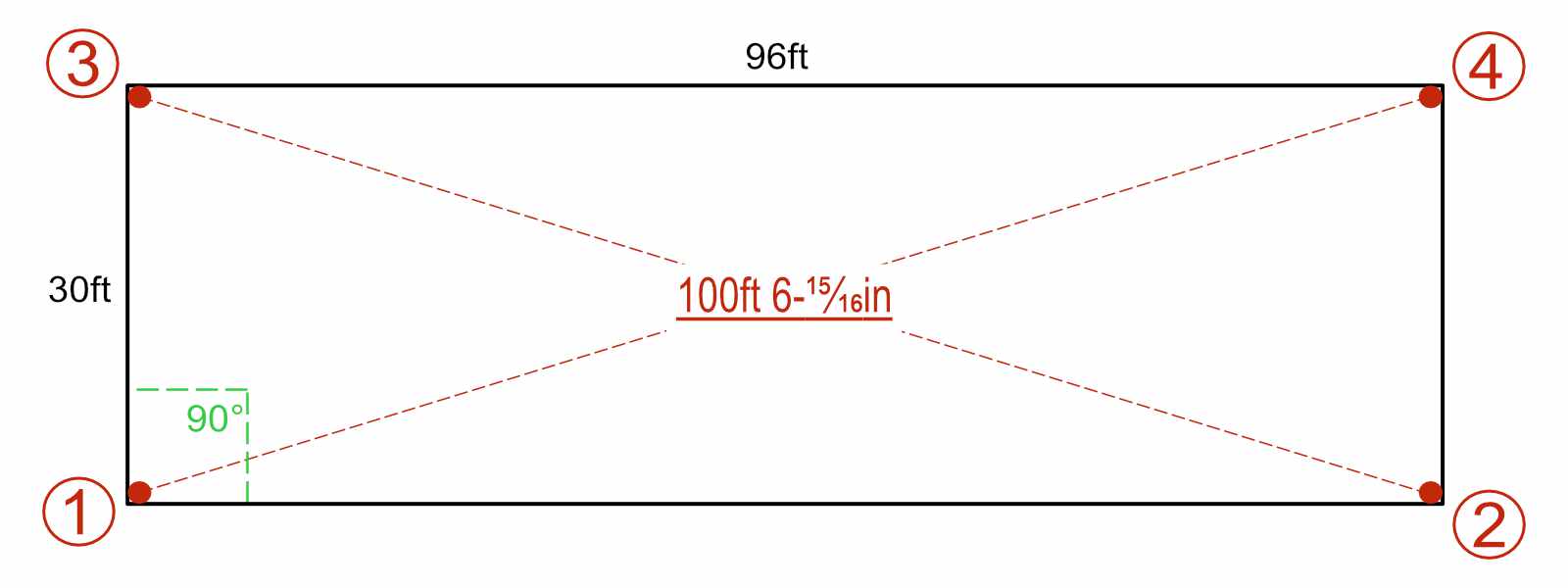

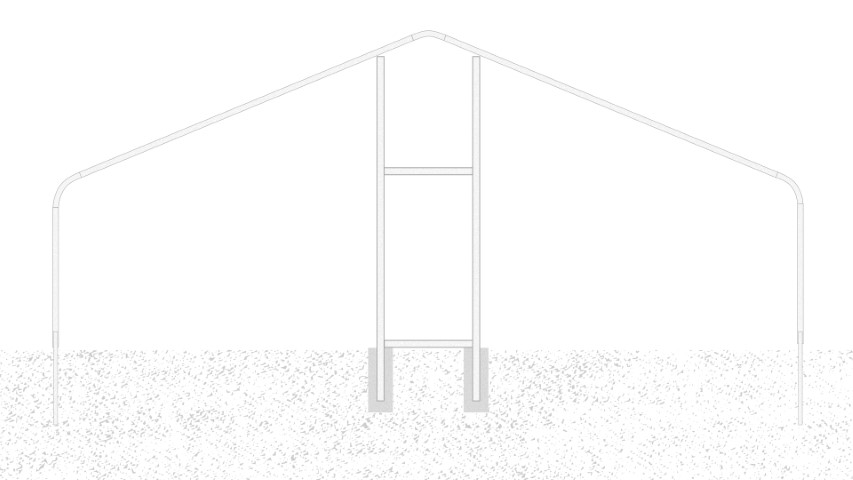

Step 1)Roll out some string line over the rebar stakes at each corner and cut 4 pieces as shown by the blue lines in the diagram. Be sure to leave string extending about 5ft beyond each corner stake. In other words, you should end up with 40ft strings for each end, and 106ft strings for each side.

Step 2)Locate the corner with the highest elevation this is where you will build the first batter board. We will call this location #1You can do this by sight, with elevation stakes, string and a string line level, with a water level, with an elevation finder app on your mobile phone, or more sophisticated surveying tools if you have access to them.

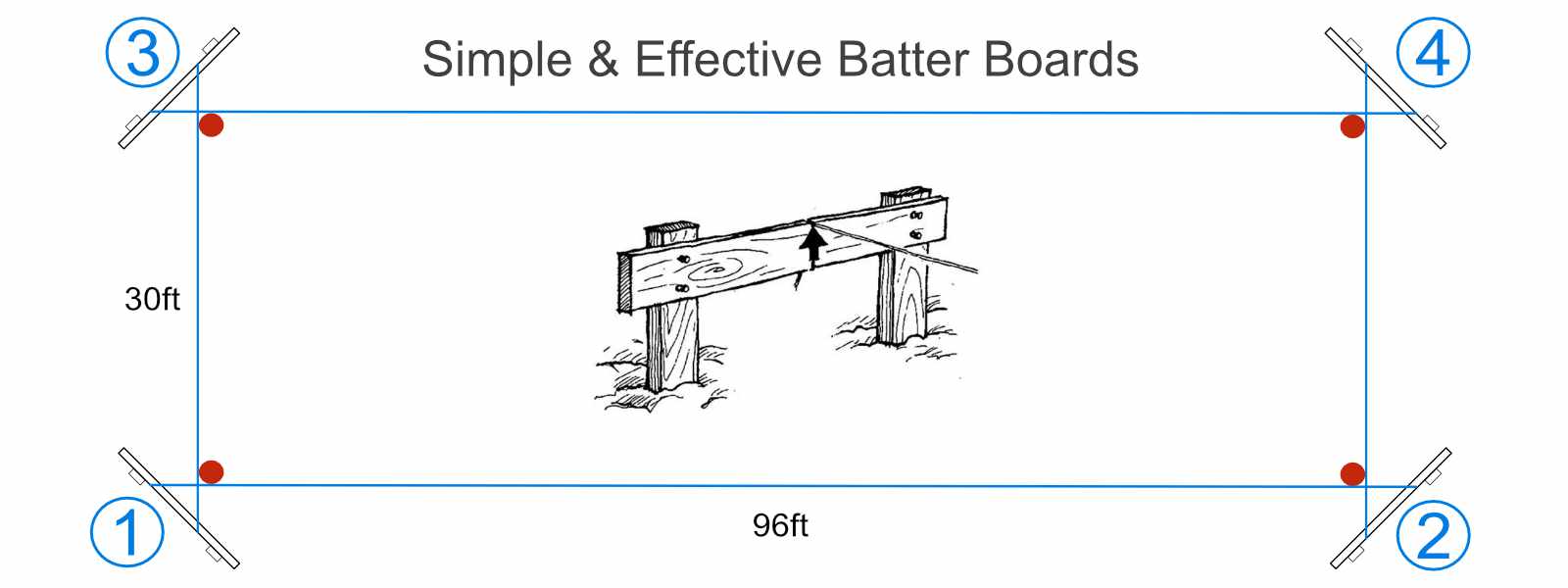

Step 3)Saw a 10ft long 1x4 in half so that you have two 5ft boards. Lay one 5ft board about 6in distance away from the rebar stake at approximately a 45 degree angle and lay the strings over the board as shown in the illustration.

Step 4)Pound in two grade stakes away from where your string will be fastened to the board and deep enough to hold the board from pulling loose and changing the string location.

Step 5) Set string line -Start at the highest elevation and fasten the batter board to the stakes using construction screws, this will allow adjustments later if needed. The top edge of the batter board should be 6 inches above the surface of the ground where your rebar stake is located and the board should be level. Fasten the string to the batter board with a screw so it passes directly over the rebar stake.

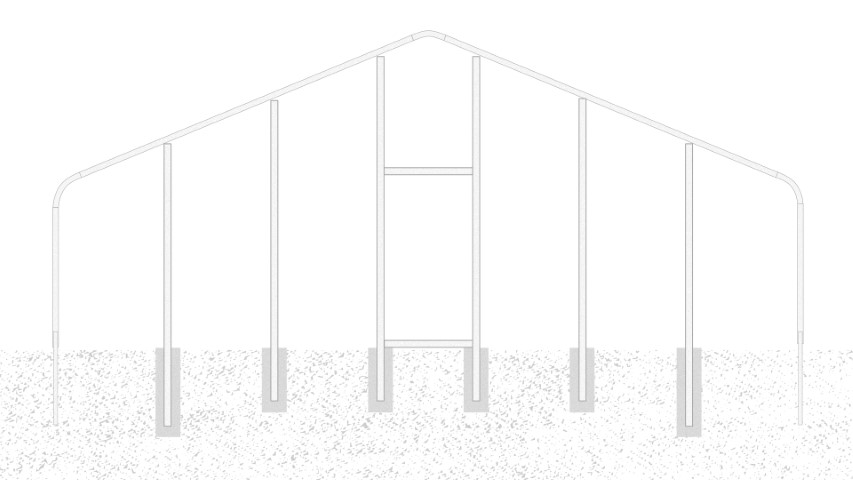

Step 6)Assuming that the highest elevation point is location #1, now move down the long side to location #2 and repeat the steps for building the batter board. Use the string line level on the line between location #1 and location #2 to determine the elevation of batter board #2 (Water level could also be used). Fasten and level batter board #2 to the grade stakes. Attach the string taught between #1 and #2 while taking care to pass the string directly over the rebar layout stake.

Step 7)Work your way around to each corner location building, leveling and adjusting the boards along with the string lines as necessary. If additional bracing is needed, the grade stakes can be pounded in at an angle and fastened to the assembly.

The level string line between locations #1 and #2 and also between locations #3 and #4 will be the reference guides for driving line posts in the next step. Make sure your batter boards are level and that the string lines pass directly over and intersect at the rebar layout stakes as shown in the diagram.